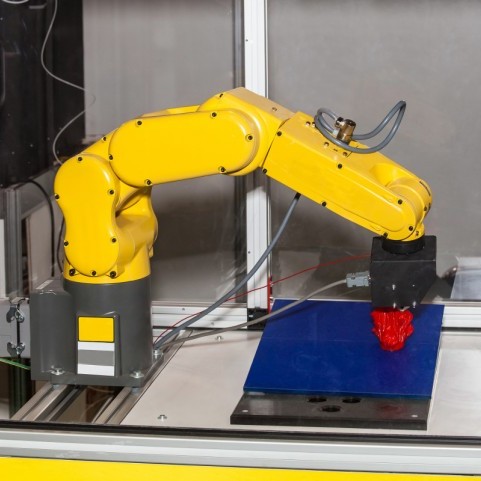

Hazardous material, filters, flammable liquids, chemical and paint storage, electrical equipment.

The threat of fire in a manufacturing plant caused by either accident or an arson attack is a risk factor that needs to be eliminated to ensure personnel safety and business productivity. Fire risks are omnipresent: from the production line, raw/finished materials, liquids, equipment, chemical and paint storage, electrical rooms and or human intervention. To tackle this mix of fire risks and to ensure business continuity, the fire protection system must have multi-level capabilities.

NFPA provides a minimum consensus level for fire protection but some risks require to go the extra mile in order to limit collateral losses and realize continuity. FirePro systems are distinctly qualified to protect multiple key assets. System modularity ensures that detection and suppression covers all potential sources of fire. As a result, detection and suppression is achieved even locally preventing the spread of fire.

FirePro’s total flooding condensed aerosol technology ensures fast, reliable and effective fire suppression without the need for activation of an auxiliary system e.g. water sprinklers. The system can even operate as stand-alone in remote locations without the need for an outside power source. Manufacturers and operators can draw further assurance from FirePro’s full compliance to the industry’s codes of practice and standards required for the protection of manufacturing plants.